MAC EX-R5-A Tank Turning Rolls

Specifications MAC Model EX-R5-A

- Input Power: AC 120 volts 60 Hz Single Phase

- Maximum load capacity per set of one drive roll and one idler roll: 11,000 lb.

- Maximum work-piece diameter: 120 in.

- Work-piece diameter range: 11.8 in. to 120 in.

- Speed Range: 4.3 to 43 in./min.

- Approximate shipping weight per set: 1,050 lb.

Above: MAC Model EX-R-5-A Tank Turning Roll with power and idler rolls at the minimum distance.

Above: MAC Model EX-R-5-A Tank Turning Roll turning a 16 inch diameter pipe.

Standard Features Model EX-R5-A Tank Turning Rolls

- Push Button Pendant Control – The hand held pendent control features a maintained Forward – Stop- Reverse push buttons along with a variable speed control dial, Emergency Stop button and 32 feet of control cable.

- Foot Control – An on/off foot control is also provided with forward and reverse switch located at the control box. A quick release plug in at the control box allows the foot control to be quickly and easily removed and stored when not in use.

- LED frequency display for speed adjustment – An AC inverter drive provides infinitely variable roll speed, long life and low maintenance. A sight window is provided at the control box to allow viewing the LED frequency display which can be used to quickly and accurately adjust the roll speed back to previous settings.

- Low Voltage Controls – The control voltage used in the pendent, foot control and switches is stepped down to 24 volts DC and fused at 0.5 amps for greater operator safety.

- Roll to Roll Adjustment - The roll to roll distance can be quickly and accurately adjusted to accommodate a wide range of work-piece diameters. The EX-R5 has one roll that is fixed and the other roll is moveable. The moveable roll is set to the desired position according the work-piece diameter and then locked into place with the lock pin. The whole process takes only seconds. This system eliminates the many problems and time consumed using drive shafts, couplings and bolts.

- Heavy Duty Machined Frame – Both drive roll and idler frame are machined after fabrication for accuracy and better alignment. This helps to reduce spiral out movement of the tank or pipe when rotating.

- Non Marring Rolls – Both the drive and idler rolls are heavy duty iron core with extra thick urethane for long life and traction. The rolls will not mar or scratch materials such as stainless steel or aluminum.

- AC 120 Volts Input Power – The EX-R5 uses AC 120 volt 60 Hz single phase input power. Allowing the rolls to be used anywhere in the shop.

- Qty 2 Heavy Duty Gear Drives – Both drive rolls are powered by a heavy duty direct gear drive and brake motor. All of the gears and bearings are fully sealed and lubricated for long life and safety.

Above: MAC Model EX-R5-A Tank Turning Roll drive and idler rolls have a heavy duty iron core with extra thick urethane for long life and traction. The rolls will not mar or scratch materials such as stainless steel or aluminum.

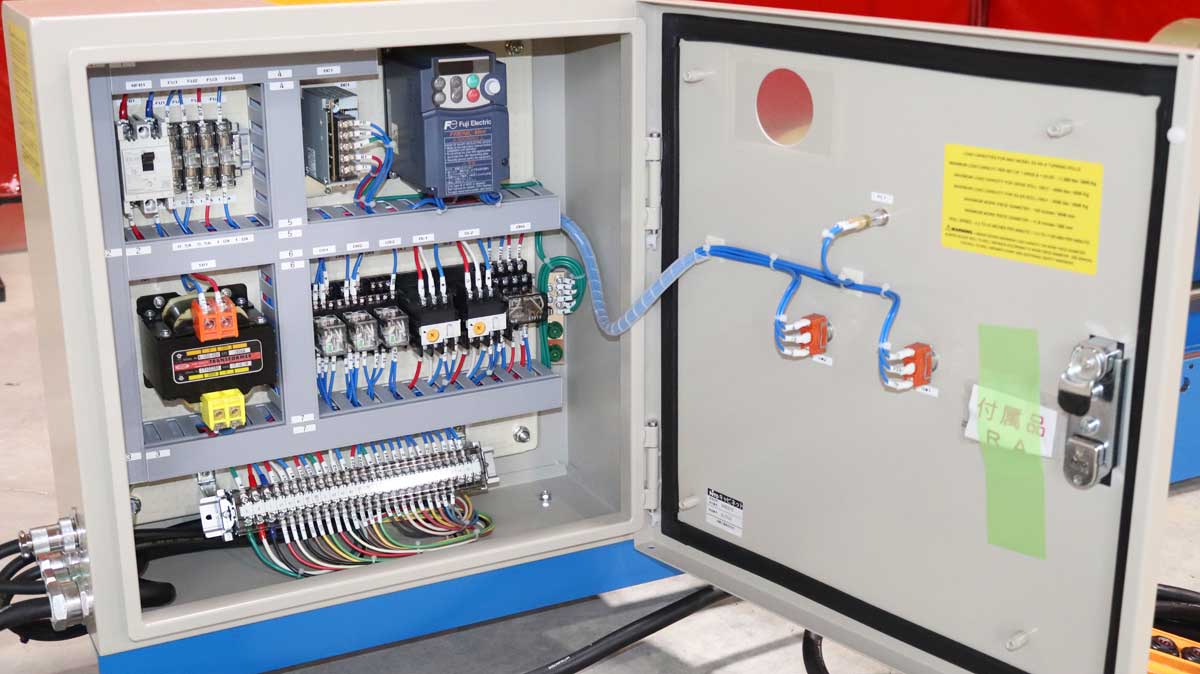

Above: MAC Model EX-R-5-A Tank Turning Roll Electrical Box.

Above Video: MAC Model EX-R5-A Turning Roll turning a 16 inch diameter pipe.

- Input Power: AC 120 volts 60 Hz Single Phase

- Maximum load capacity per set of one drive roll and one idler roll: 11,000 lb.

- Maximum work-piece diameter: 120 in.

- Work-piece diameter range: 11.8 in. to 120 in.

- Speed Range: 4.3 to 43 in./min.

- Approximate shipping weight per set: 1,050 lb.

All-Fab Corp. has sold hundreds of Tank Turning Rolls throughout North America over the past 25 years. See just a few of the Tank Turning Rolls we have sold being used in production .